SEL unveils circuit board factory in Moscow

Assembly team expected to join the elite ranks of its kind

Schweitzer Engineering Laboratories’ new printed circuit board factory in Moscow is poised to become one of the top 10 producers of its kind in the nation by the end of 2024.

The printed circuit boards go to SEL’s manufacturing centers in Pullman, Lewiston, West Lafayette, Ind., and Lake Zurich, Ill.

As important as the factory is to SEL, it’s also getting noticed industry-wide in an environment where companies are “desperate” for reliable suppliers of printed circuit boards, SEL CEO Dave Whitehead said at a ribbon cutting for the factory Wednesday.

If people return in the future, SEL may have more capacity to manufacture printed circuits boards “not only ourselves, but to a whole bunch of other customers,” Whitehead said.

His remarks were part of the event at the factory that began operations in March. The site is named the Schwartz Campus in honor of Ron Schwartz, the first vice president of quality at SEL.

Idaho Gov. Brad Little and Washington U.S. Rep. Cathy McMorris Rodgers were among the more than 130 elected officials, business partners, community members and SEL employees who attended.

The vertical integration in Moscow strengthens SEL’s work of inventing, designing and manufacturing digital products and systems that protect and control electric power systems, according to SEL officials.

The technology prevents blackouts and allows its customers to improve power-system reliability, safety and cost.

“We believe it’s the cleanest board factory in the world and certainly the most automated,” said SEL President and Chief Technology Officer Edmund O. Schweitzer III.

All of the water and chemistry at the plant are recycled in a zero-liquid discharge process that has helped earn SEL an environmental excellence award from the Idaho Association of Commerce & Industry for 2023.

“We design our boards,” Schweitzer said. “And now, we can make them right here ourselves instead of sending the work out to others.”

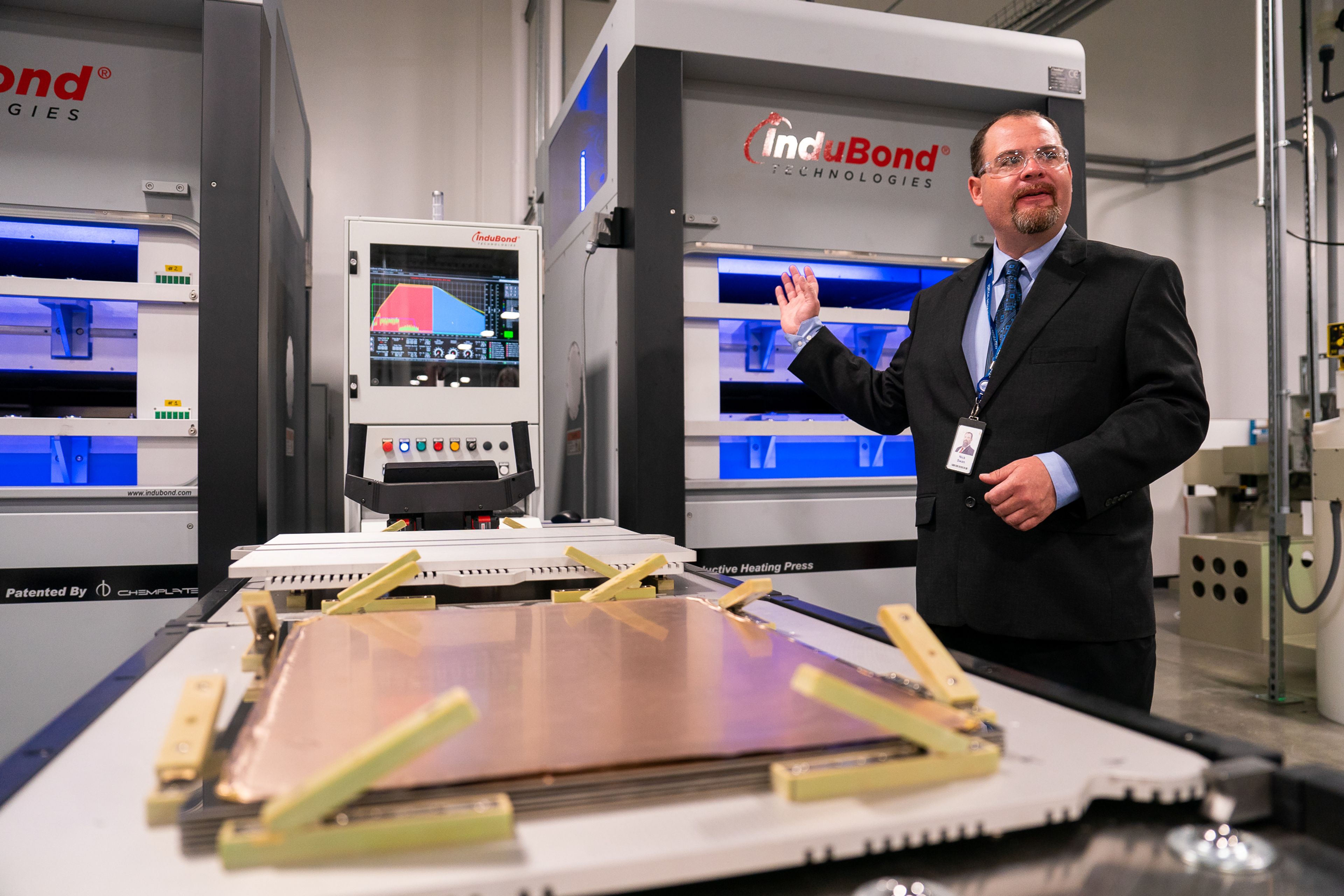

Printed circuit boards function as the nerve center of electronic devices such as cellphones and all SEL devices, said SEL’s Engineering Director, John Hendrickson.

“The primary purpose is to provide the medium to mount electronic components and then provide the electronic signal between those components,” Hendrickson said. “... They are critical to ensuring the best quality and reliability for SEL.”

The number of U.S. printed circuit board manufacturers has dwindled to about one-tenth the number of what it was 40 years ago, Schweitzer said.

“Large companies bought these smaller companies that outsourced all of the business to China namely,” he said. “We don’t like that. We don’t want our artwork going to other countries. We want to maintain the integrity of our designs. We depend on U.S. suppliers today.”

SEL’s solution to make printed circuit boards in-house reflects its values, Schweitzer said.

“For decades, many businesses seem to believe, when in doubt, ship it out,” he said. “We’re different. I like to say with a grin, ‘Bring it in.’”

The audience laughed and clapped after that remark.

In addition to giving SEL more control over its supply chain, the $100 million, 162,000-square-foot facility allows SEL to shrink the time between finishing a design for a new printed circuit board and having it ready for testing to one or two days.

Whitehead recalled instances earlier in his career when he would wait anxiously for printed circuit boards he had designed that would be ready in one or two weeks if they were put on a rush order.

“It is such a way to speed up our process,” Whitehead said. “To be able to get these designs done and in the hands of our customers sooner, it’s quite a capability.”

Little and McMorris Rodgers congratulated SEL, with McMorris Rodgers noting that SEL is the largest private employer in the region.

SEL has 6,557 employees total. Of those, 55 are in Moscow, 2,685 are at its Pullman headquarters and manufacturing center and another 944 are in Lewiston.

The careers at SEL and its contractors create opportunities for young people to stay in Idaho, Little said.

“Maybe one of my grandkids will be somewhere here in this area for the next SEL whiz-bang gizmo, something that I don’t understand, but I would be delighted to be here,” he said.

The innovations at SEL are part of an American tradition of leading the world in technological inventions that have lifted people out of poverty and raised the standard of living, McMorris Rodgers said.

Utility companies, mines, factories, hospitals, universities and data centers in countries throughout the world are among those that benefit from SEL’s work, she said.

With the completion of the Schwartz Campus, SEL is again “leading the way” for the region and the country, McMorris Rodgers said.

“This facility means more jobs, more opportunity for everyone in eastern Washington and Idaho and beyond,” McMorris Rodgers said.

Williams may be contacted at ewilliam@lmtribune.com or (208) 848-2261.